1. Overview

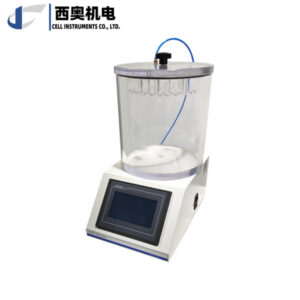

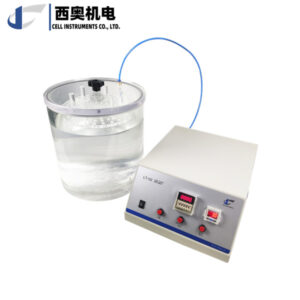

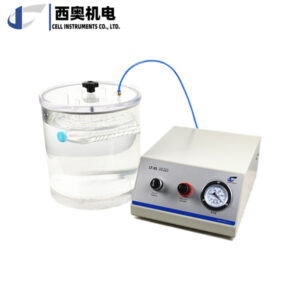

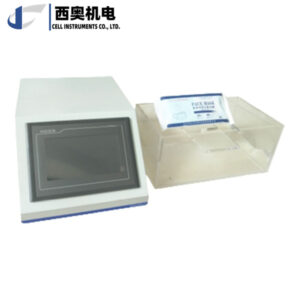

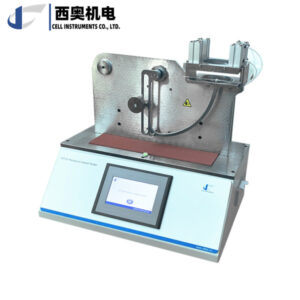

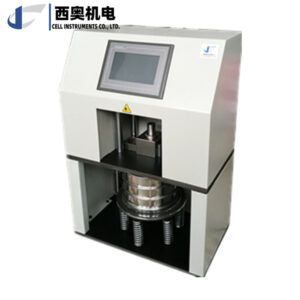

Sealing tester, also known as soft package sealing tester, is a key equipment to ensure the quality of various packaging products. LT-01/02/03 sealing tester plays an important role in food, pharmaceutical, daily chemical, electronics and other industries with its advanced technology and excellent performance. It can accurately detect the sealing performance of soft packages, provide scientific and accurate data for manufacturers and testing institutions, and help them optimize packaging technology and improve product quality.

2. Application

1. Basic Applications

It is mainly used for the overall sealing test of various packaging bags, packaging containers and other samples. Whether it is a common food packaging bag or a medicine packaging bottle, it can be strictly tested for sealing performance through this tester to ensure that the product is not affected by the external environment during transportation and storage.

(II) Extended Application

- Stationery products:For example, ballpoint pen refills, etc., the sealing test can ensure that the ink will not leak and extend the service life of the product.

- Electronics:Plays a key role in waterproof and sealing testing, ensuring that electronic equipment can work normally in various environments and avoid damage due to water ingress.

- Medical Devices:The sealing test of medical devices is particularly important, which is directly related to the patient's safety and treatment effect.

- Simulated negative pressure environment test:Other test items simulating negative pressure (high altitude) environmental conditions can be carried out to meet the sealing performance testing needs of different products in special environments.

(III) Application industries

- Government testing agencies:Quality inspection institutes, food and drug inspection, customs, scientific research institutions, universities and colleges, etc., used for quality inspection and research of various products.

- Packaging Industry:Manufacturers of packaging bags, packaging containers, etc. use sealing testers to monitor product quality and improve market competitiveness.

- Food, pharmaceutical and other industries: The packaging material manufacturer should ensure that the packaging used can effectively protect the product and prevent deterioration and contamination.

- Third-party testing agency:Provide customers with professional packaging sealing performance testing services and issue authoritative test reports.

III. Necessity

In today's highly competitive market environment, the quality of product packaging directly affects the company's reputation and economic benefits. A small sealing problem may cause product leakage and deterioration, leading to serious consequences such as consumer complaints and recalls. Therefore, it is very necessary to use a sealing tester to conduct strict sealing performance testing on packaging. It can help companies:

- Guarantee product quality:By testing the sealing of the packaging, we can ensure that the product maintains good quality throughout its life cycle and reduce product damage caused by packaging problems.

- Reduce costs:Discover and solve packaging sealing problems in advance to avoid costly losses due to product quality issues, such as returns, compensation, etc.

- Meeting regulatory requirements:In the food, pharmaceutical and other industries, strict regulations require that product packaging must have good sealing properties. The use of sealing testers can help companies meet these regulatory requirements and avoid legal risks.

- Enhance brand image: High-quality packaging can enhance the grade and brand image of products and enhance consumers’ trust in products.

4. Working Principle

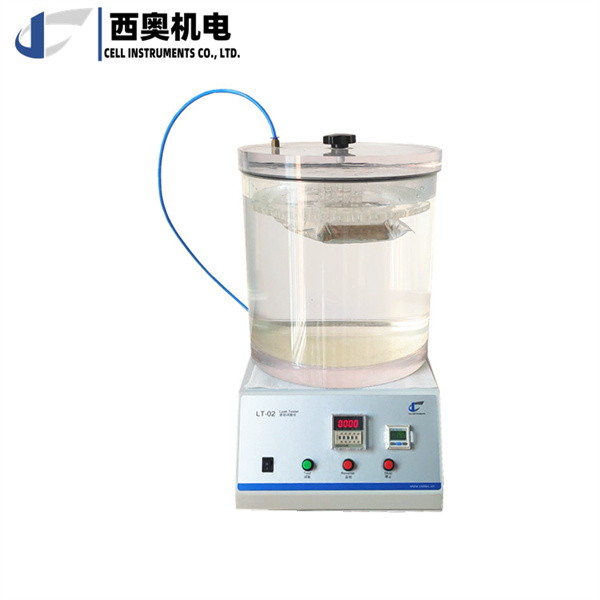

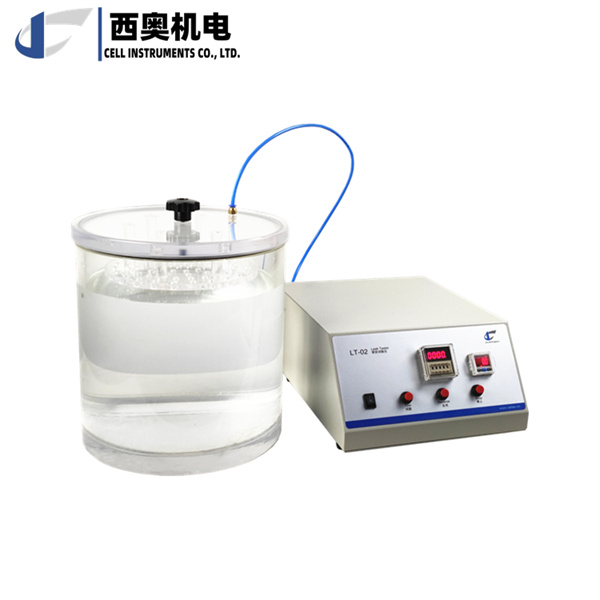

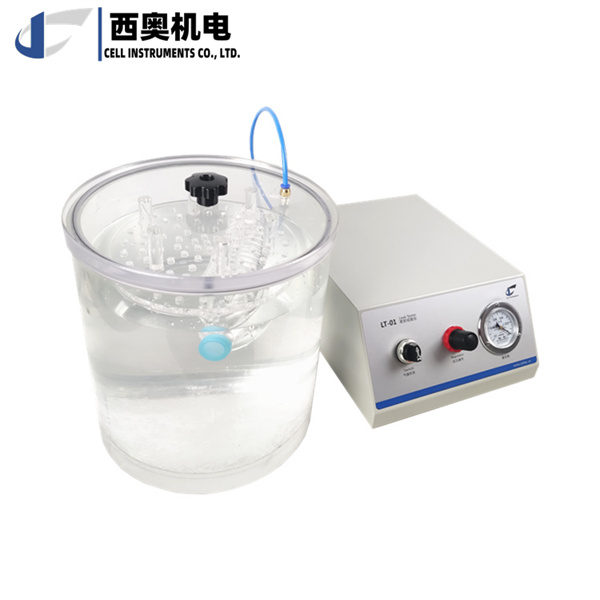

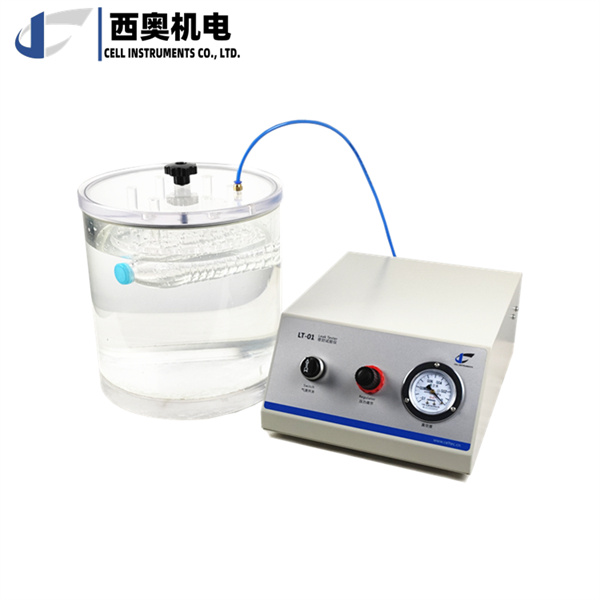

Principle A

By evacuating the vacuum chamber, a pressure difference is generated between the inside and outside of the sample immersed in water. At this time, observe the escape of gas or the infiltration of water in the sample to determine the sealing performance of the sample. If bubbles emerge, it means that the package is leaking and the sealing performance is unqualified; otherwise, the sealing performance is good. This method is intuitive and simple, and can quickly detect obvious leakage points in the package.

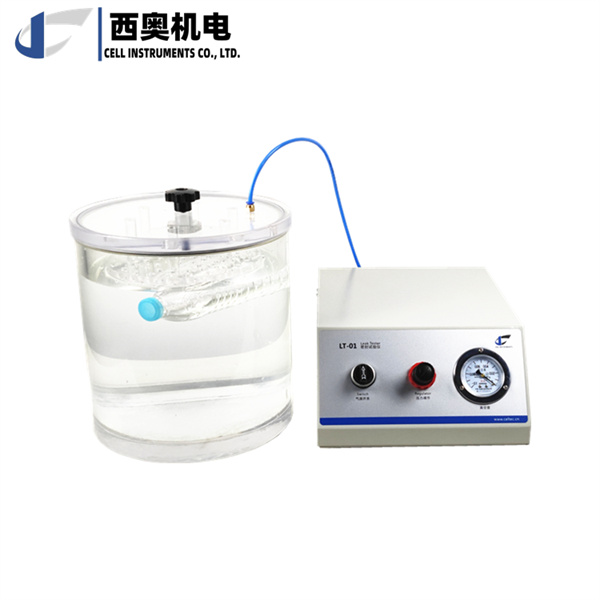

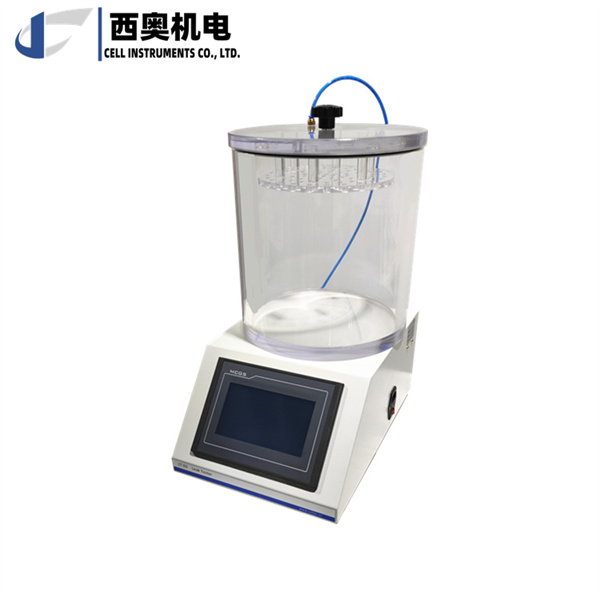

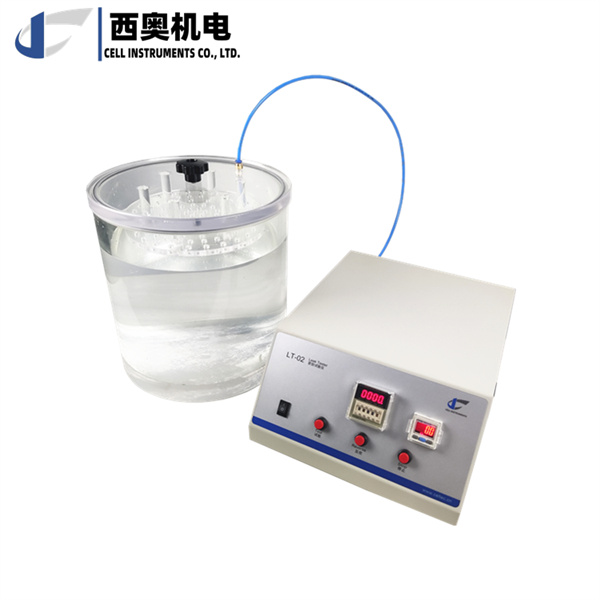

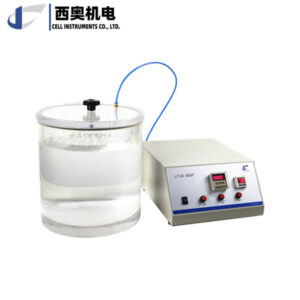

Principle B

By evacuating the vacuum chamber to create a pressure difference between the inside and outside of the sample, the expansion of the sample and the recovery of the sample shape after the vacuum is released are observed to determine the sealing performance of the sample. If the sample expands excessively during the vacuuming process, or cannot return to its original shape after the vacuum is released, it means that there is a problem with the sealing performance of the package. This method can detect some potential sealing defects, such as insufficient sealing strength.

V. Technical specifications

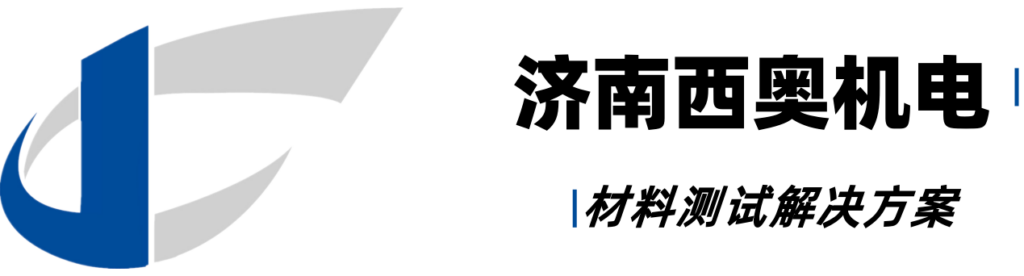

| LT-01 | LT-02 | LT-03 |

| Ultra-thick vacuum organic glass vacuum chamber to avoid yellowing, cracking and other effects on observation results | ||

| Various types of vacuum chambers can be customized according to different samples | ||

| Use well-known brand vacuum generator to ensure pressure stability during vacuum generation | ||

| Automatic vacuum maintenance and back-blowing unloading | ||

| The experimental process is fully automatic | ||

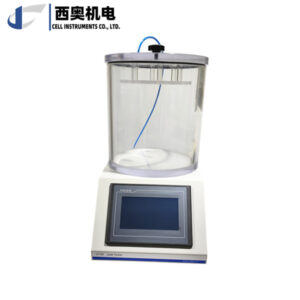

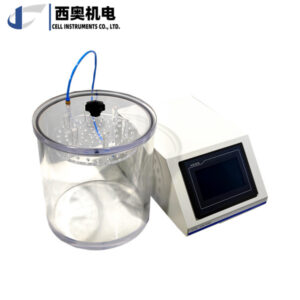

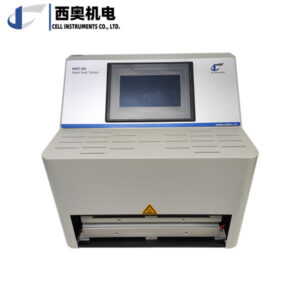

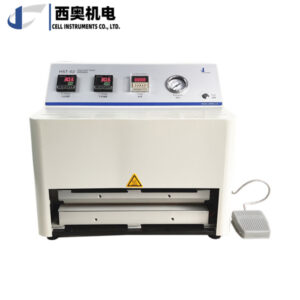

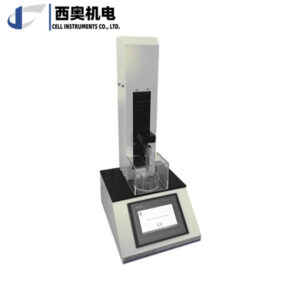

| 7-inch HMI touch screen | Digital pressure and time display | No power required |

| Five groups of test parameter design and storage | ||

| Automatic statistics and storage of experimental results | ||

6. Advantages

- Extra thick vacuum plexiglass vacuum chamber:Avoid yellowing, cracking and other factors that affect the observation of results, ensure clear visibility of the test process, and improve the accuracy of detection.

- Adopt famous brand vacuum generator:Ensure the pressure stability during the vacuum generation process and ensure the reliability of the test results.

- Automatic vacuum maintenance and back-blowing unloading:The operation is more convenient, reduces manual intervention and improves work efficiency.

- The experimental process is fully automatic:Reduces the impact of human factors on test results and improves the accuracy and repeatability of the test.

- 7-inch HMI touch screen:The operation is simple and intuitive, making it convenient for users to set parameters and view results.

- Five groups of test parameter design and storage: Multiple groups of test parameters can be stored according to different test requirements for easy use next time.

- Automatic statistics and storage of experimental results:It is convenient for users to manage and analyze test data and provide a basis for product quality improvement.

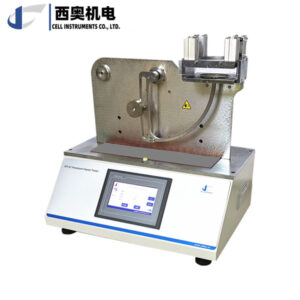

7. Configuration and accessories

- Host: Including core components such as vacuum chamber, vacuum generator, control system, etc.

- Operation Manual:Detailed introduction to the operation methods, maintenance and other contents of the equipment for the convenience of users.

- Data cable: Used for data transmission and device connection.

- Optional accessories:According to user needs, vacuum chambers, fixtures and other accessories of different sizes can be provided to meet diverse testing needs.

8. Standards

- GB/T 15171 Test method for sealing performance of flexible packaging: The commonly used test standard for sealing performance of flexible packaging in China.

- ASTM D3078 Standard Test Method for Determination of Leaks in Flexi-ble packaging by Bubble Emission: An internationally accepted standard for leak detection of flexible packaging.

IX. Support and Training

- Technical Support: Provide 24-hour online technical support to answer any questions users encounter during use at any time.

- Training Services:Provide users with professional operation training to ensure that users can master the use of the equipment.

Reviews

There are no reviews yet.